MEDIA

A Comprehensive Guide to Choosing the Right CNC Turning Center

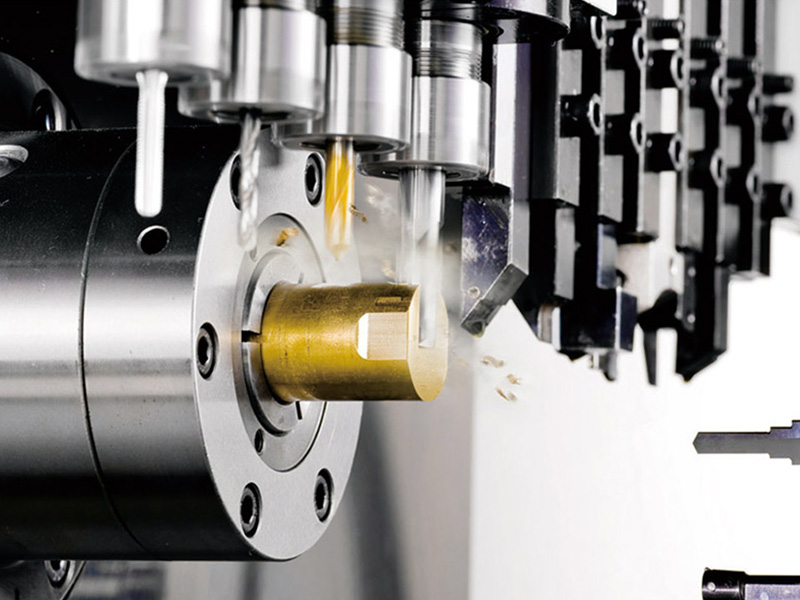

Introduce the significance of CNC turning centers in modern manufacturing processes and the importance of selecting the right one for specific needs.

1. Understanding Your Requirements:

- Discuss the types of workpieces you will be manufacturing.

- Consider the materials you will be working with (metals, plastics, composites, etc.).

- Evaluate the required precision and tolerances for your parts.

- Estimate the production volume and required turnaround time.

2. Key Features to Look For:

- Precision and accuracy: Discuss the importance of spindle accuracy, repeatability, and tooling precision.

- Rigidity and stability: Highlight the significance of machine rigidity for vibration damping and chatter reduction.

- Flexibility: Explore the ability to handle various workpiece sizes and shapes, as well as tooling options for different operations.

- Automation capabilities: Discuss the availability of features like automatic tool changers, bar feeders, and robotic integration for unmanned operations.

- Control system: Evaluate the user interface, programming capabilities, and compatibility with CAD/CAM software.

3. Considerations for Specific Applications:

- Prototyping and small batch production: Discuss the importance of quick setup and changeover times, as well as flexibility in programming.

- High-volume production: Highlight the need for reliability, durability, and ease of maintenance to minimize downtime.

- Complex geometries: Evaluate the machine's capabilities for multi-axis machining and simultaneous operations.

- Exotic materials: Consider features like high-speed machining, coolant systems, and chip management for efficient processing of difficult-to-machine materials.

4. Budget and Total Cost of Ownership:

- Discuss the initial investment cost and ongoing operational expenses, including energy consumption, tooling costs, and maintenance.

- Evaluate the potential return on investment based on increased productivity, reduced scrap rates, and improved quality.

5. Researching and Comparing Options:

- Utilize manufacturer specifications, customer reviews, and industry recommendations to create a shortlist of potential CNC turning centers.

- Consider visiting trade shows, arranging demonstrations, and seeking input from industry experts to make informed decisions.

6. Conclusion: Summarize the key points discussed in the article and emphasize the importance of thorough research and evaluation in choosing the right CNC turning center for your specific needs.